Narikoma Food Co., Ltd. (Kobe Central Kitchen (Kobe Factory)/Construction of Logistics System)

Challenges

- Construction of a new factory increased sortation volume requirements.

- Needed to drastically eliminate sorting errors.

Results

- Introduced an Automated Storage and Retrieval System (ASRS) using Multishuttle to fully automate replenishment and storage under temperature-controlled conditions.

- Using the Super Pick Director (SPD), an automated picking system, we were able to achieve near zero human error in sortation.

BackgroundConsolidation of nursing home meals caused a huge increase in sorting volume, resulting in much greater occurrence of human error.

Background

Consolidation of nursing home meals caused a huge increase in sorting volume, resulting in much greater occurrence of human error.

Narikoma Food Kobe Central Kitchen started full-scale operation in March 2022.

Narikoma Food Co., Ltd., which provides food services to healthcare and other public institutions nationwide, recently built a factory dedicated to nursing home foodservice. Until this new facility went into operation, foodservice for nursing homes was prepared at two of the several factories that Narikoma Foods has located throughout Japan. With the consolidation of nursing home food service at the new Kobe Factory, major issues came to light, specifically around sortation. First, efficiency had to be improved in order to handle the higher volume of sortation required to fulfill orders for nursing homes nationwide.

Second, sortation errors could not be tolerated. Meals had to be sorted by occasion--breakfast, lunch or dinner--as well as by ingredients which could be life-threatening if a patient has allergies.

Improve Efficiency With Zero Sorting Errors

Improve Efficiency With Zero Sorting Errors

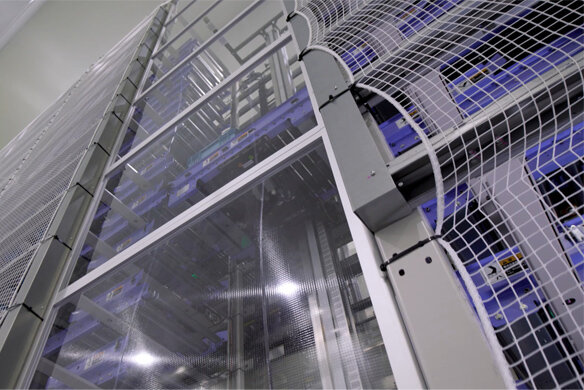

The sortation area in the factory relies on two core technologies for process improvement. Those are the Multishuttle System, automated storage and retrieval system, and the Super Pick Director (SPD) to pick the required product. Food is produced at a separate location under automated, sanitary conditions. Once food products are completed, they are placed in a food tray called banju, and transported from the production floor to sortation/shipping floor by a vertical conveyor. In the sorting area, an identifying barcode on the food tray is read, and then stored in the high throughput, space-saving Multishuttle system. The quality of the food is maintained through strict temperature control at every process.

Based on the order, the Multishuttle will pick the food tray in sequence, and deliver it to the correct location for replenishment. Narikoma Foods has drastically saved on labor by completely automating the replenishment process.

With the introduction of the SPD on the collection line, we were able to greatly automate picking from shelves. During order fulfillment, a returnable tote with RFID readable tag is sent to a film inserter, and new order data is written to the RFID at the same time one order is bagged. Just prior to transport to collection conveyor, the order data written to the RFID is read, confirming the starting food tray.

The SPD was then implemented to automate the pick process, making errors virtually non-existent. The indicator on the SPD system flashes with the quantity to be picked so all the operator has to do is follow the indicator without any thinking about items to be picked.

Weight is also checked on the auto-feed system. Product picked in advanced are transported in sequence based on when corresponding returnable tote arrives and automatically picked. This automated pick process has not only significantly improved productivity, it has virtually eliminated the human error that had plagued sorting processes in existing plants.

Since the process is so easy to understand, training time of new hires is greatly reduced, allowing operators to begin working practically the same day. Further, because of a much lighter workload, there is significantly less employee turnover. Even when the line is in full operation and the Multishuttle system is running, it is possible to see status of inventory replenishment in real-time and ship automatically. The system is constantly replenished with Multishuttles so orders are never shorted. By securing stable inventory allocation, order fulfillment is more efficient.

After collection is completed, the bags with the meal products are bound automatically by machine. It is then finally transported to the consolidation area where it is packed in collapsible totes for shipment. The collapsible totes containing the meals are loaded onto dollies destined for factories around the nation, and then on to the end user customer.

What’s Next?We will continue to provide stable meal supply at an extremely high level of accuracy.

What’s Next?

We will continue to provide stable meal supply at an extremely high level of accuracy.

The Kobe factory currently produces only soft meals, however, going forward it plans to expand production to meet all the nursing care meal needs. In order realize Narikoma Food’s goal of delivering delicious, good food for the elderly toward making them happy, Toyo Kanetsu will continue to support the company with cutting-edge material handling systems that support a stable supply of food at an extremely high level of shipping accuracy.

* Source: Based on an interview conducted July, 2020. Data, organizational departments and personal names appear as they were at time of interview.

Products and Services Introduced