- We started sales of the SPD III in 1981, and since then, we have refined and developed the technology and our know-how over 40 years, enabling us to flexibly respond to the changing needs of customers. As a result, we have the largest market share for solutions designed for co-ops.

Pick Director System

Super Pick Director(SPD®)Ⅲ:

Multi-Oder/Guide Lamp/Synchronous

Improved picking productivity for high-frequency items.

Designed to improve picking accuracy and productivity for situations where the number of items are relatively few.

Designed to improve picking accuracy and productivity for situations where the number of items are relatively few.

Nationwide Co-ops and many others

Line Belt Conveyor

Features

-

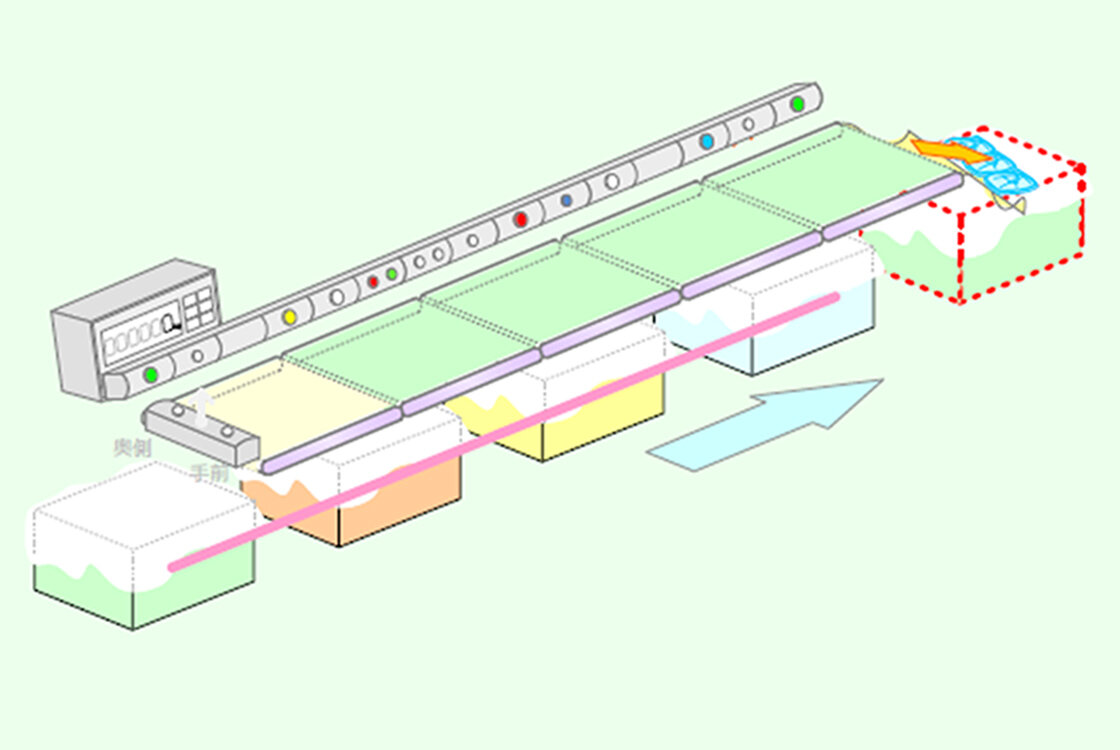

We design and engineer the optimal system according to picking frequency and number of orders.

-

Peripheral equipment such as auto labelers, automatic loading devices, and temporary storage shelves are available.

-

A lamp guides the worker to place items in order tote, making it virtually error-proof.

-

With the display lamp, picking can be done in advance, further reducing wait time of the operator.

Display (item unit/IU)

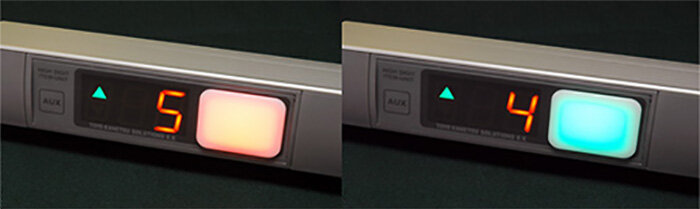

- Lamp to guide operator makes the process virtually error-proof. Front/back zones can be distinguished by changing lamp color to prevent mistakes.

- The 7-segment LED is large and easy to see.

Automatic Replenishing

Scale for Confirming Weight

Picking Work (Conveyor Side)

Set in a fixed position, the sensor is blocked.

- Set Put Location

- → Reduce possibility of wrong put later in the process.

- Store 5 Orders

- → Possible to pick in advance.

- Scale for Confirming Weight

- → Detects errors in quantity.

Other Products in Picking/Allocating Systems

Catalog Download

Submit the form below to download catalog.

Download Catalog