-

Compared to other conventional systems, Multishuttle ASRS takes 25% of floor space.

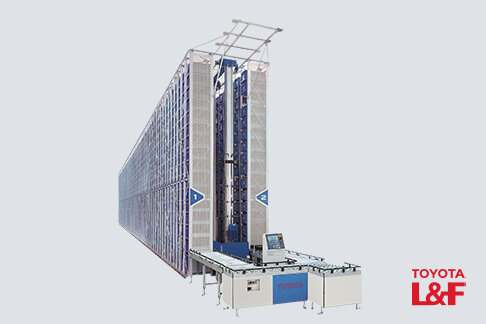

Multishuttle

The Multishuttle ASRS saves space yet delivers high performance.

By incorporating all of the major warehousing functions of picking, sorting (order fulfillment), replenishment, and storage,

we can design and engineer a system to uniquely meet the the needs of your operation.

By incorporating all of the major warehousing functions of picking, sorting (order fulfillment), replenishment, and storage,

we can design and engineer a system to uniquely meet the the needs of your operation.

Features

- Items in racks are delivered to the pick station in the desired sequence (such as by category, store destination, route order, etc.).

- Order Consolidation and Fulfillment

-

Can also be installed on a gantry or mezzanine.

- Space saving (25% or more reduction)

- Do more with less equipment (high capacity with less equipment).

- Maximize utilization rate (high capacity/performance allows for a reduction in man-hours)

- Energy saving (35-70% reduction)

- Easy maintenance (simple structure, few failures and easy recovery)

- By making use of wasted space above on a rack, there are many possibilities to flexibly store and deliver products, parts, work-in-process parts and assemblies.

- Since the shuttle is compact, storage is highly efficient.

- The optional double-reach shuttle can store multiple cases behind one another on shelves, further improving storage efficiency.

![Picking [GTP: No-walk picking]](/products-info/products-info/common/icon_17.png)

- Product is delivered directly to the operator for “no-walk picking.”

- Since items are delivered to the pick station in the desired sequence, walking to pick product is completely eliminated, which dramatically improves productivity.

Four Main Shuttle Functions

Picking [GTP: No-walk picking]

- Product is delivered directly to the operator for “no-walk picking.”

- Since items are delivered to the pick station in the desired sequence, walking to pick product is completely eliminated, which dramatically improves productivity.

Sorting/Packing (order fulfillment)

- Items in racks are delivered to the pick station in the desired sequence (such as by category, store destination, route order, etc.)

- Order Consolidation and Fulfillment

- Compared to sortation equipment, a multishuttle system saves space.

Storage

- By making use of wasted space above on a rack, there are many possibilities to flexibly store and deliver products, parts, work-in-process parts and assemblies.

- Since the shuttle is compact, the storage is highly efficient. Furthermore, the optional double-reach shuttle can store multiple cases behind one another on shelves, further improving storage efficiency.

Replenishment

- Replenishment is also automated for just-in-time deliveries.

Other

- Modular construction allows for easy expansion.

- Can also be installed on a gantry or mezzanine.

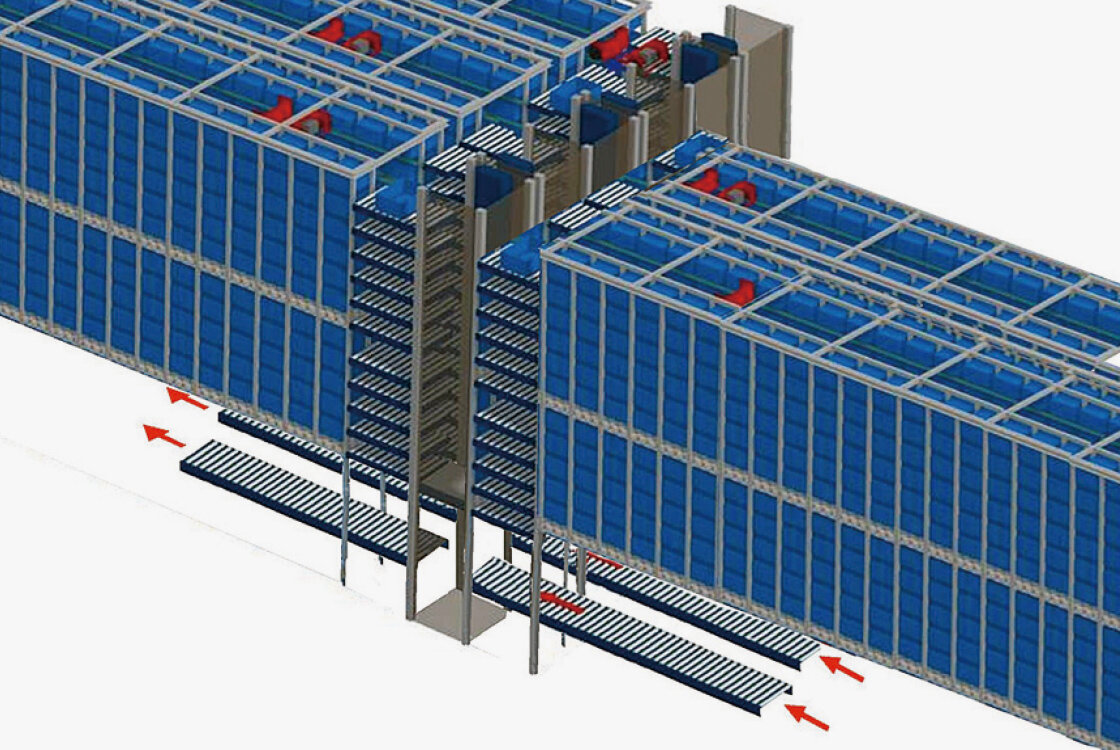

RapidPass: Transfer material between racks and aisles

- Product is moved between aisles as opposed to bringing it out. In doing so, products to be picked are consolidated in one aisle to be delivered to one workstation. This has eliminated the need for sequencing/buffering conveyors and complicated controls used in the past, significantly reducing equipment costs.

Tandem Layout

- Maximize system capacity by installing racks on either side of lift.

- The TKSL Multishuttle system is the leader in delivering high-speed warehousing functionality.

- The lift can store and retrieve a maximum of two cases at once.

Other Products in Storage Systems

Catalog Download

Submit the form below to download catalog.

Download Catalog