Predictive Maintenance Service

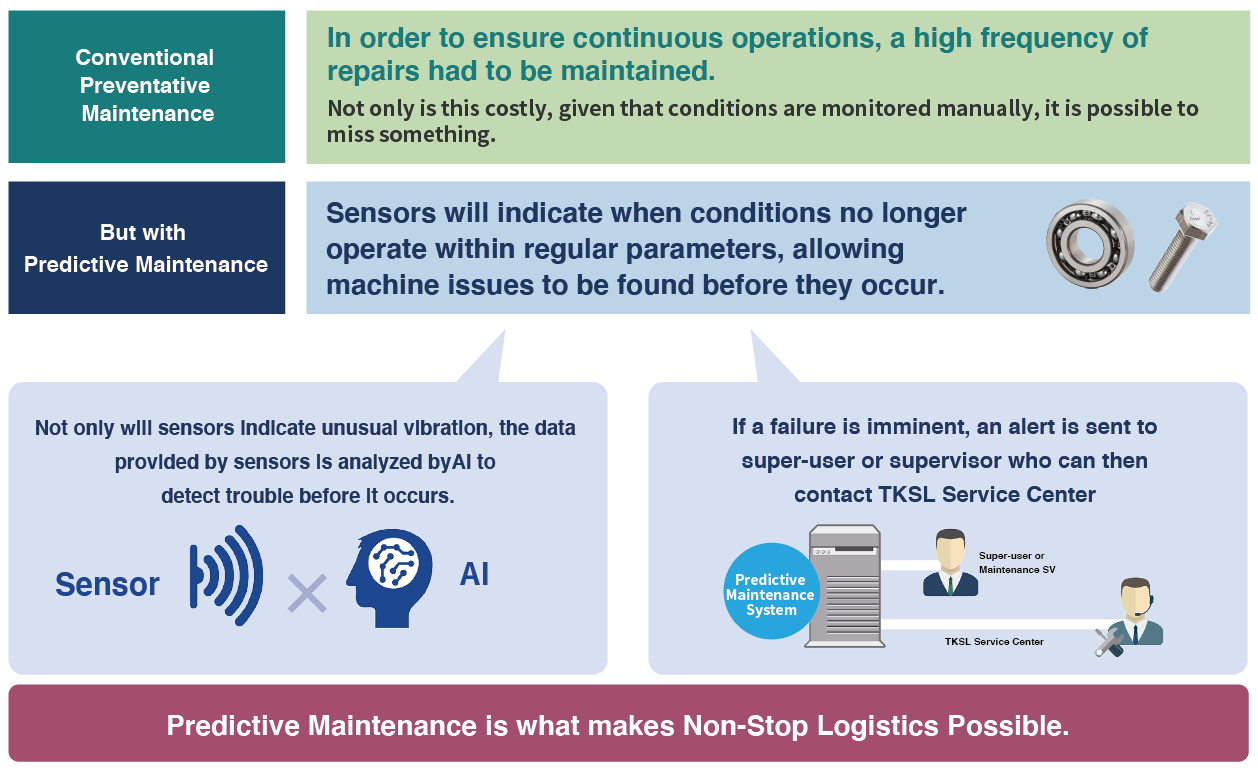

Achieve non-stop logistics operations by going a step beyond "preventive maintenance" to "predictive maintenance".

Today's increasingly technologically sophisticated equipment enables AI to reliably predict potential issues, giving you the ability to proactively address a failure before it has a major impact on operations.

Achieve non-stop logistics operations with predictive maintenance.

Conventional Preventive Maintenance

Predictive Maintenance

Regular Inspection Work

Done Manually

Automated by the system

Inspection Method

Lines had to stop to perform inspections

No line-stop required, continuous monitoring

Evaluation Criteria

Difficult to assess suspect parts without data

Uses machine learning with concrete vibration, temperature and noise data

Accuracy

Quality of maintenance outcomes depends on the judgment and experience of service technician

Improved accuracy based on quantitative AI data analytics

Quality of Work

Part replacement workmanship depended on a manual checklist

Sensors detect minor defects in workmanship

Sudden Machine Trouble

Sudden machine trouble depended on the inspection cycle

With continuous monitoring, sudden machine trouble is zero

| Conventional Preventive Maintenance | Predictive Maintenance | |

|---|---|---|

| Regular Inspection Work | Done Manually | Automated by the system |

| Inspection Method | Lines had to stop to perform inspections | No line-stop required, continuous monitoring |

| Evaluation Criteria | Difficult to assess suspect parts without data | Uses machine learning with concrete vibration, temperature and noise data |

| Accuracy | Quality of maintenance outcomes depends on the judgment and experience of service technician | Improved accuracy based on quantitative AI data analytics |

| Quality of Work | Part replacement workmanship depended on a manual checklist | Sensors detect minor defects in workmanship |

| Sudden Machine Trouble | Sudden machine trouble depended on the inspection cycle | With continuous monitoring, sudden machine trouble is zero |

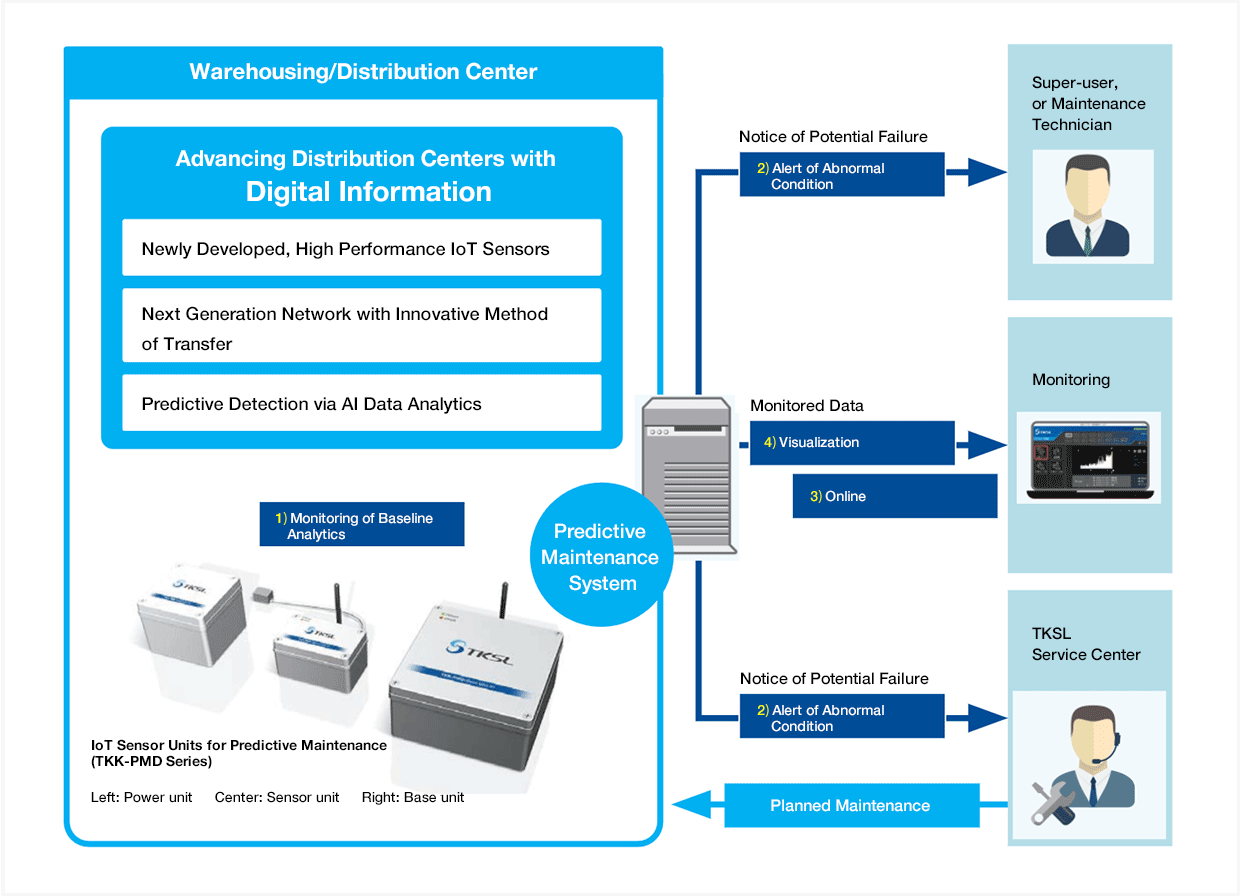

Predictive Maintenance System

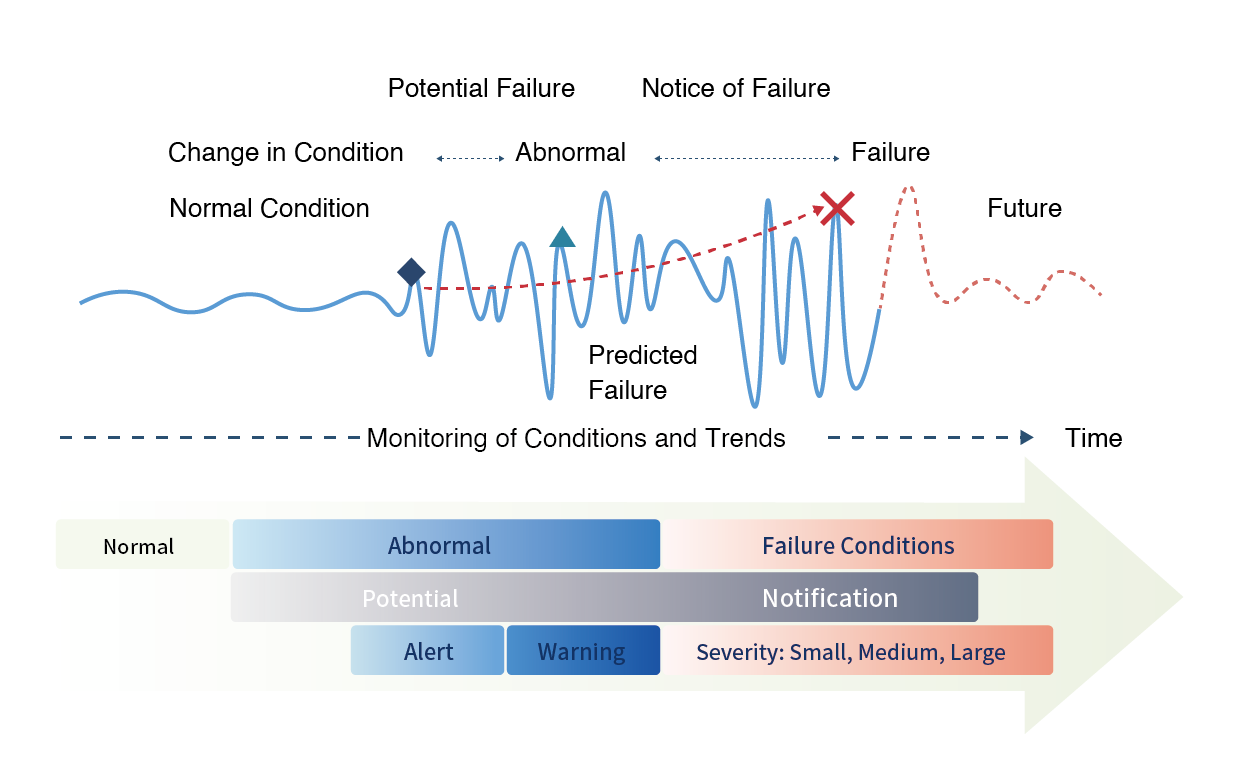

Overlooking subtle changes in vibration of equipment is not an option!

Fluctuations in data are analyzed by AI to signify potential failures and issue an alert.

Predicting Abnormal Conditions and Equipment Failure

We offer the following service contracts.

Product Plan

- Can be purchased as a standard plan.

- The longer you use the plan, the better the cost performance over time.

Subscription Plan

- No up-front cost required.

- There is a fixed, monthly payment.

Product Plan

- Can be purchased as a standard plan.

- The longer you use the plan, the better the cost performance over time.

Subscription Plan

- No up-front cost required.

- There is a fixed, monthly payment.

Catalog Download

Submit the form below to download catalog.

Download Catalog