History

1941

Founded as Toyo Kanetsu Kogyo K.K.

1955

Yokohama Conveyor Plant opened, and started manufacturing and sales of Toyo Conveyor.

1960

Technical tie-up with Rapistan, USA

1961

Delivered Japan's first sortation system to Toyota Motor Corporation, Kasuga Warehouse.

1969

Delivered Japan's largest sortation system with 129 chutes to Seiyu Store Fuchu Distribution Center.

1973

Delivered BHS (Baggage Handling System) to New Tokyo International Airport (Narita Airport).

1978

Delivered Japan's first high-speed sorter (sorting capacity of 7,400 cases per hour x 2 systems) to Ito-Yokado Saitama Center.

1981

Expanded into overseas markets by delivering a BHS to Manila International Airport (Philippines) and Singapore Changi Airport (Singapore).

Developed and delivered Japan's first digital picking system, the Pick Director, for a major toy manufacturer in Japan.

Case Study

1983

Completed development, engineering, and integration of the largest, mass-retailer distribution center which used emerging digital technologies and data systems. (Nada Kobe Co-op, Kanagawa Co-op)

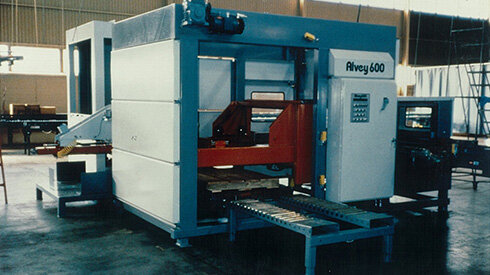

Technical tie-up with Alvey from the United States to introduce the company's palletizer system.

1985

Developed and delivered the world's first cleanroom-compatible robotic stacker crane (US IBM).

Delivered Max Sorter, the largest automatic sorting system in Asia, to Chukyo Sagawa Express's Komaki Distribution Center.

1986

Delivered various food manufacturing and packaging solutions to Japan's first, full-scale comprehensive food processing center (Co-op Citizens' Co-op Sapporo Ishikari Plant).

1988

Designed and completed an automated storage and retrieval system for Japan Airlines (Japan Airlines Haneda Facility).

1989

Acquired exclusive sales rights for hanger sorters in Japan from Promech in the Netherlands, and entered into logistics for the apparel industry.

1990

Delivered the main material handling equipment (case sorting machine, automatic case transfer machine, etc.) to the world's most advanced post office, Shin-Tokyo Post Office.

1992

Established TKK Service System Co., Ltd. (100% subsidiary of Toyo Kanetsu K.K.)

Delivered BHS to New Tokyo International Airport (Narita Airport), Terminal 2.

1993

Delivered BHS and air cargo equipment for use in a passenger terminal on the west side of Tokyo International Airport (Haneda Airport).

Delivered the world's first ultra-high speed sorting machine using electromagnetic switching technology, and the New Posi-Sorter (Seiyu Fuchu Center, Daiei Logistics Systems Yokohama RDC, etc.).

1995

Acquired exclusive distributor rights in Japan for sales of automatic picking machines from Austrian company, PEEM.

1996

Received an order from Coco's Japan for comprehensive engineering and development of a large-scale project including consultation on equipment but also design of the building.

1997

Designed and installed the world's first conveyor system for an auction distribution system and delivered to Kyushu Nikkan Botanical Co., Ltd. It received the Logistics Technology Grand Prize Award.

Development and delivery of Mini Posi-Sorters for sortation of accessories.

1998

Designed and developed a fully automatic picking system for tobacco products (TS Network Co. in Tokyo, Chubu, Kansai, Kyushu).

Developed a parallel sorter that reduced the running speed by 25% and significantly improved durability while maintaining the sorting capacity, and delivered it to Sagawa Express's large-scale truck terminal.

Delivered one of the world's largest BHS to the Kuala Lumpur International Airport (Malaysia).

1999

Obtained ISO9001 certification.

Began Japan's first cross-industry alliance with IXI Technologies, a company known for its warehouse management system.

2000

Introduced advanced logistics systems into ASKUL, a large EC company in Japan. Jointly received the Grand Prize for Advancements in Logistics with Hitachi.

2001

Company name changed from TKK Service System K.K. to K Techno K.K.

Delivered a reconfigured logistics systems that included IT advancements to Co-op Kobe.

(Received the 2002 Award for Automatic Identification Systems jointly with Co-op Kobe).

2002

Concluded a strategic business alliance with Siemens Dematic of Germany

Toyo Kanetsu K.K. Logistics Business Division was spun off to become Toyo Kanetsu Solutions K.K.

2003

Reconfigured and upgraded the truck terminal using a new airless concept, a first in Japan.

2004

Developed a next-generation fulfillment system with a climbing sorter, and delivered it to the Japanese Consumers' Co-operative Union.

Delivered a BHS to Haneda Airport Terminal 2.

2005

Delivered a BHS to Chubu International Airport (domestic and international flights).

Opened RFID demonstration and testing facility "HP RFID Noisy Lab Japan" at Chiba Office.

2006

Obtained ISO14001 certification.

2007

Established "Kanetsu World" at Chiba Office to introduce new TKSL technologies.

2008

Concluded a golden partner contract with Riva, Inc.

Set up partnership with C-NET Co., Ltd. for sales of voice recognition systems.

2009

Delivered the first Ecoloveyor® to Sound House.

2010

Developed and delivered a high-speed, automatic storage/retrieval system based on use of multishuttles for use at major EC company.

Delivered a BHS and CHS (Cargo Handling Systems) to Tokyo International Airport (Haneda Airport).

2014

Delivered an expanded/updated BHS system to Tokyo International Airport (Haneda Airport).

Completed renovations on the Wakayama Plant No. 1 done to improve quality levels and production capacity, and upgraded processing/painting equipment.

Established an alliance with Toyota Industries Corporation.

2015

Merged the maintenance subsidiary K-Techno K.K. with TKSL.

Wakayama Plant No. 2 renovations were completed with the goal of increasing production, as well as expanding floor space for assembly and storage.

2016

Headquarters relocated on the occasion of the 75th anniversary of Toyo Kanetsu K.K.

Delivered Japan's first multishuttle GTP (Goods-to-Person) to a major EC company.

Established an alliance with ISHIDA Co., Ltd.

Concluded a partnership contract with Jaroc Co., Ltd.

2018

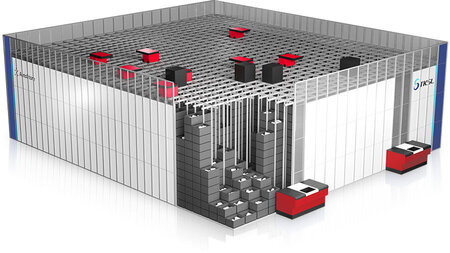

Began sales of AutoStore, a system that fulfills two roles: ultra-high density storage and high speed picking.

Obtained OHSAS18001: 2007 certification.

2019

Reintegrated Toyo Kanetsu Solutions back into Toyo Kanetsu K.K.

Began operations under the name of Solutions Division.

Completed renovations of Wakayama No. 3 Plant with the purpose of increasing production capacity, and expanding assembly and storage area.

Obtained ISO45001: 2018 certification (migrated from OHSAS18001: 2007).

* With the issuance of ISO 45001: 2018, OHSAS18001: 2007 will be abolished (March 11, 2021).

Development and sales of Full-Line GTP, which provides unprecedented labor savings, and efficiency while maintaining social distance.

Introduced Japan's first counter-installed SBD (Self Bag-Drop) in Terminal 2 at Chubu International Airport.

Also installed a hybrid, facial recognition SBD system at Haneda International Airport, Terminal 2 and 3. (2020)

2020

Developed and started sales of Predictive Maintenance Service that detects and predicts equipment failures using AI and IoT.

Introduced an AutoStore installation at Wakayama Plant No. 3 for the purpose of consolidating parts storage and improving warehousing efficiency.

Marked our first introduction of our Predictive Maintenance Service at a distribution center of a major precision equipment manufacturer.

Delivered the first AutoStore to Nippon Express.

2021

Introduced a roller processing machine at Wakayama Plant No. 1 for the purpose of expanding production volume and shortening lead-time.

2022

Established a partnership agreement with Rapyuta Robotics, Inc.

Established a distributorship agreement with Zhejiang Libiao Robots Co.

Established distributorship agreement with Modula S.P.A.

2023

Opened satellite service centers in Tsurugashima, Nagareyama, and Atsugi to improve customer response time.

Acquired Scrum Software Inc. as a subsidiary.

Delivered the first Modula to Komatsu.

2024

Delivered the first T-sort (Table-sorting system) to MITSUI-SOKO HOLDINGS.