Toyo Kanetsu K.K. is pleased to announce that it has joined forces with Zhejiang Libiao Robots Co., Ltd.

(Headquarters in Hangzhou, Zhejiang Province, President: Zia Huiling) to bring the sorting robot, T-Sort, to customers in Japan.

1. Background and Purpose

Toyo Kanetsu K.K., under the slogan of " ACTION FOR THE FUTURE," is working to develop and build logistics systems through Monozukuri that exceed customer expectations by finding and executing new and innovative technologies. We are happy to join forces with Libiao which designs, develops, manufactures, sells and services the T-Sort and peripheral equipment.

With a declining workforce and rising demands of short delivery windows and small orders on e-commerce, companies are looking for innovative ways to save labor to meet the new demands on distribution centers.

With the conclusion of this agreement, Toyo Kanetsu K.K. will add the T-Sort functionality to its core offerings of WMS, picking, sorting, storage and other labor-saving solutions to improve productivity and solve problems companies are facing toward develop game-changing solutions.

2. Company Profile of Libiao

(1) Company Name

Zhejiang Libiao Robots Co., Ltd.

(2) Establishment

July 21, 2016

(3) Headquarters

Hangzhou, Zhejiang Province, China

(4) Representative President

Xia Huiling

(5) Business

Development of AMR (sorting robots) controls software; design, manufacture, sales and service

of hardware for China and global markets.

(6) Capital

Approx. 170 million yen (10 million yuan @ 17 yen/yuan)

(7) Net sales

505 million yen (FY2020)

(8) Number of employees

150 (May 2022)

3. Outlook

We believe that the impact on our performance for this fiscal year and next fiscal year will be minor.

Inquiries

Corporate Planning Department, Corporate Headquarters, Toyo Kanetsu Co.

TEL:03-5857-3333 E-mail:tksl-info@toyokanetsu.co.jp

About the Sorting Robot ( T-sort)

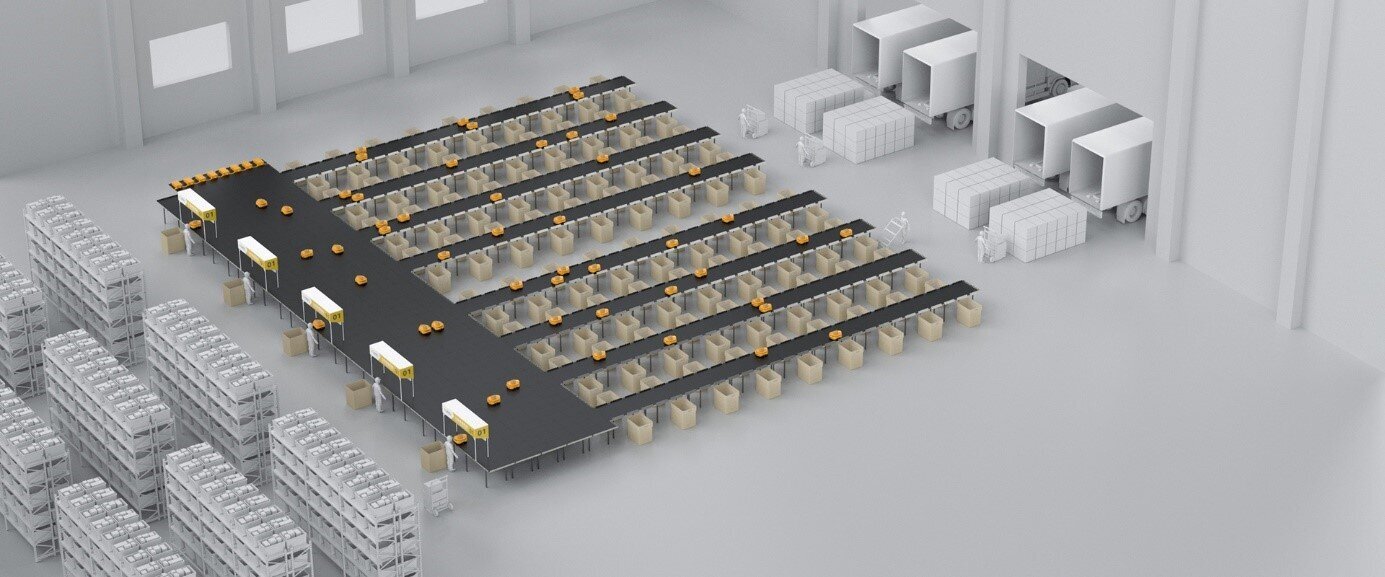

With T-Sort, the sorting robots travel along an optimized route on a specialized floor covering to transport and sort material.

Compared to conventional fixed equipment such as conveyors and sorters, the layout and number of robots is highly flexible because robots can be increased and decreased depending on needs, and the footprint for the same throughput is about half of a conventional sortation system.

With more than 20,000 robots in operation in 20 countries in industries such as EC, retail, 3PLs, apparel, and pharmaceutical, the performance of the system has a proven track record of reliability.

Sorting Robot (T-sort)

Application Examples