Completed in October of 2019, operations at Plant No. 3 were fully launched.

In October 2014, we completely upgraded our sheet metal fabrication equipment, and in July 2015, we completed construction of the assembly building. Finally, we integrated and centralized the production management system with the purpose of streamlining all operations from receiving of materials, to processing, assembly, and shipping. These improvements have allowed us to shorten lead times while improving quality.

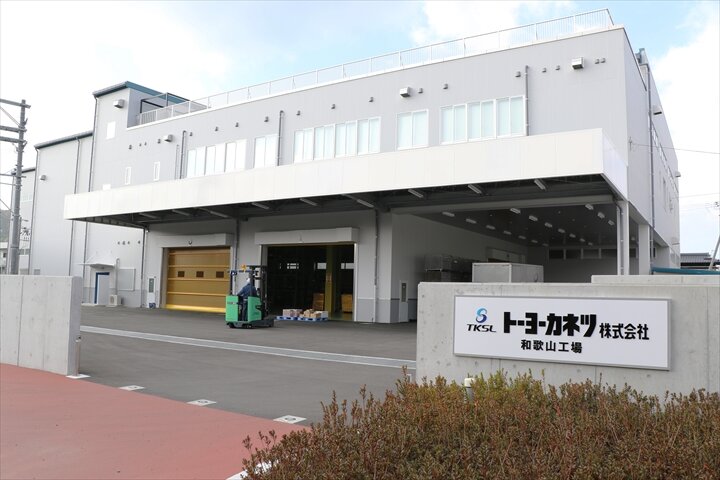

With robust growth in capital investment, particularly in labor saving automation, Plant No. 3 at Wakayama will give us the ability to further respond to increased demand.

The new plant is two stories with a total floor area of 4,610 m2. Receiving, warehousing and shipping operations are located on the first floor. On the second floor, the Ecoloveyor® is assembled and finished goods are stored.

We have also made an agreement with No, Arita Neighborhood Association that the plant can be used as a temporary evacuation location in the event of disaster. The roof of the plant will be able to accommodate about 200 people in the event of earthquake or other disaster. We have also stored emergency rations and water in the warehouse in case of such an emergency.

The completion of the plant will give us the ability to expand production to meet greater demand, while improving quality and production efficiency.

Introduction to Plant No. 3

Assembly Area

Storage Area

Rooftop Shelter

Stockpile

Butsuryu Truck