Biznet Corporation (Construction of a Warehousing/Distribution Center)

Mr. Eiji Yamamoto (Executive Officer, General Manager of Systems Department)/Mr. Hiroshi Kakizaki (Logistics Manager)

Challenges

- Complete review of operations to improve efficiency.

- Develop a logistic operation that can handle a 100% increase in shipping volume.

- Ensure the safety and security of the environment toward gaining greater reliability for customers.

Results

- Improved ship times by 20%

- Improved picking efficiency in order to handle 80,000 order lines.

- Improved contracts as a result of visits to the center.

BackgroundCreate a base for expanded logistics operations and services.

Background

Create a base for expanded logistics operations and services.

We needed a warehousing and distribution system that plays a critical role in providing better logistics services in order to meet customers' ever diversifying needs. With a new distribution center, our aim was to expand picking capacity from 40,000 order lines using existing equipment to 80,000 order lines, while doubling our maximum shipping volume. Our goal was to establish a new Tokyo Distribution Center that not only expanded distribution operations and volume in East Japan, but also improved logistics services for our customers. Biznet offers a service called “Tsuide Bin” in which we handle specialized forms and novelty items for multiple clients, and as those clients have become more sophisticated in their awareness of compliance. They have concerns about their important assets being handled by a 3PL. One of the goals with this distribution center was to achieve an operation that is “SFS”–Safe, fast and simple. Toyo Kanetsu took care to implement many features to meet that goal and achieve those higher standards.

Reasons We Chose Toyo Kanetsu Solutions:Toyo Kanetsu has been a trusted business partner for many years.

Reasons We Chose Toyo Kanetsu Solutions:

Toyo Kanetsu has been a trusted business partner for many years.

Based on the outcome of bidding, we chose the Hitachi Industries/Toyo Kanetsu Solutions Group because they understood our business model the best. Also, Toyo Kanetsu had a clear program of maintenance and improvement which put our minds at ease. Naturally Biznet has a midterm and long term vision. Part of that vision is the expansion of the distribution center to support future growth. Because the proposed maintenance program was so well outlined and defined, we knew that the Hitachi/Toyo Kanetsu team would be involved in the future as well. Because they paid such attention to detail about our after-launch operations, we knew that with them as our business partner, we could have a win-win relationship.

BenefitRecognized a dramatic improvement in efficiency with an overall reduction in time-to-ship of 20%.

Benefit

Recognized a dramatic improvement in efficiency with an overall reduction in time-to-ship of 20%.

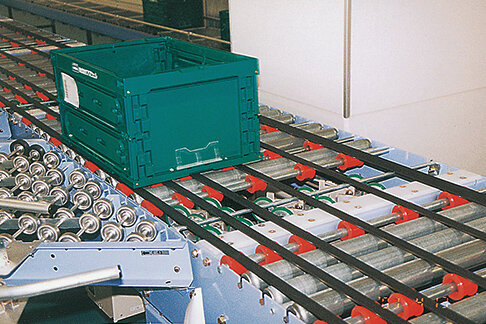

In order to accommodate the doubling of volume shipped, we expanded the warehouse space by 25%, concentrated operations on the first floor, and improved equipment layout to promote much improved efficiency. A complete review of operations was done based on the improved equipment layout and as a result, the time-to-ship was improved by 20%. Furthermore, the improve efficiencies resulted in a 13% improvement in the timing of order fulfillment. By automating previously manual processes such as the input of packing lists and introducing scanning elsewhere, we have been able to considerably speed up the process by automating the handling of packing slip, pick list and shipping labels. The Tokyo Logistic Center now also has a line to handle large items which did not exist before. Prior to introduction of the line for large items, we picked those items manually because of the inefficiencies they caused in our digital picking system. Now however the hit rate for automatically handling these items is well over 50% greater. Overall, the efficiency has improved by 8%.

BenefitIncreased contract rate after visits to the center.

Benefit

Increased contract rate after visits to the center.

One issue during design of the center was how to make lines flexible and adaptable to avoid a line stoppage during peak order times. In the lines at the center, we are able to do such rerouting on lines in order to handle maximum shipping volumes. Line stoppage has been kept very low, and with the proper programs in place, we continue to keep it low for a downtime rate of only 2%. Because of our improved shipping speed, we have been able to achieve same-day shipments to the Yokohama/Kawasaki area for an overall significant improvement for our customers. The improved operations at the Tokyo Distribution Center has contributed to an overall increase in the contracts Biznet handles because customers can clearly see the safety and security measures that have been implemented. We have reached the targets that put us on the road to achieving our vision, but will continue to look forward to the future support from Hitachi/Toyo Kanetsu as we work to improve the quality of our services.

* Source: Based on an interview conducted March 2009. Data, organizational departments and personal names appear as they were at time of interview.

Products and Services Introduced